Graphite Sintering Mould For Diamond

A Graphite Sintering Mould for Diamond is a special tool made from graphite used to help create synthetic diamonds. It can handle very high heat and pressure without breaking. This mould makes sure the diamonds form evenly and come out strong and high-quality. It is an important part of making diamonds in factories.

Description

A graphite sintering mould for diamond is an important tool used in the production of diamond tools like cutting blades, drill bits, and grinding wheels. It plays a big role in how well the diamonds are shaped and how strong the final product is. The quality of this mould affects the overall performance of the tools made with it.

Our graphite sintering mould is made from high-purity isostatic graphite, which means it can handle very high temperatures (about 1350°C to 1600°C) without changing its shape. Unlike metal moulds, it doesn’t bend or get damaged easily when it gets hot. This helps keep the diamond particles evenly spread inside the mould, so the final product is strong and consistent.

Graphite is also great at spreading heat quickly, which helps the mould heat up and cool down faster. This allows the diamond and the mould to expand and shrink together, reducing cracks and damage during the process. It also makes the finished tool more accurate in size and shape.

Another benefit of graphite is that it works well with diamonds. Metal moulds can sometimes react with diamonds at high temperatures and cause them to lose strength. But graphite moulds do not react with diamonds, so the diamond’s original hardness and shape stay the same. This makes the tools more durable and wear-resistant.

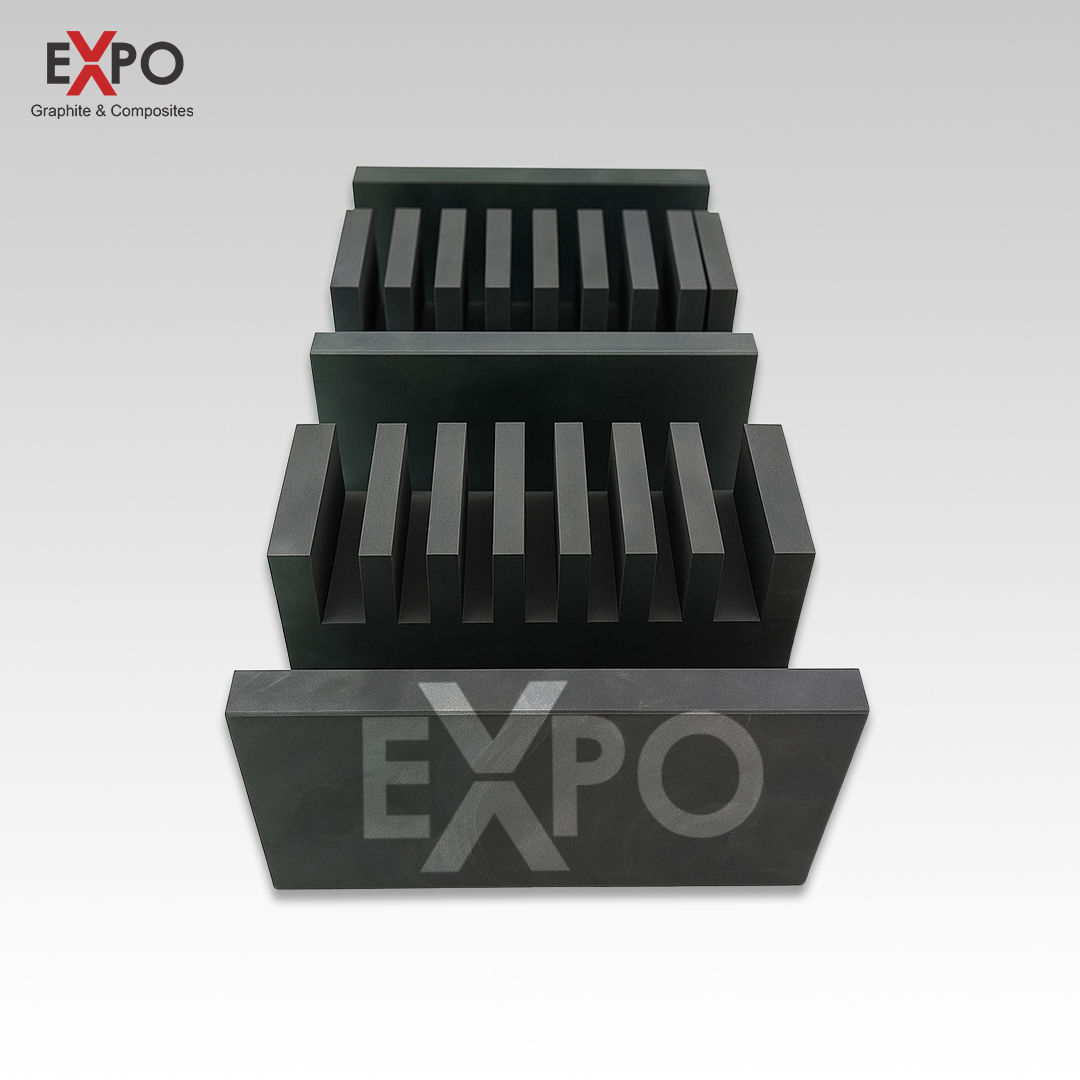

Also, graphite is easy to shape. We can create moulds with complex and custom designs like those needed for saw teeth or drill heads. The mould also allows even air and heat to move through it during the sintering process, helping to make sure every part of the tool is processed evenly and without defects.

5 Main Benefits of Our Graphite Sintering Mould for Diamond:

- Handles High Temperatures: The mould stays strong and stable even at very high heat, making sure the diamond tools come out well-shaped.

- Better Size and Shape Accuracy: Graphite helps prevent cracks and keeps the final tool accurate in size and design.

- Keeps Diamonds Strong: Unlike metal, graphite doesn’t damage or weaken the diamonds during heating, helping them stay hard and effective.

- Supports Complex Shapes: It’s easy to make special moulds for tools with tricky designs like saw blades or drill bits.

- Even Heat and Air Flow: The mould’s structure allows heat and gases to spread evenly, reducing defects and improving tool quality.