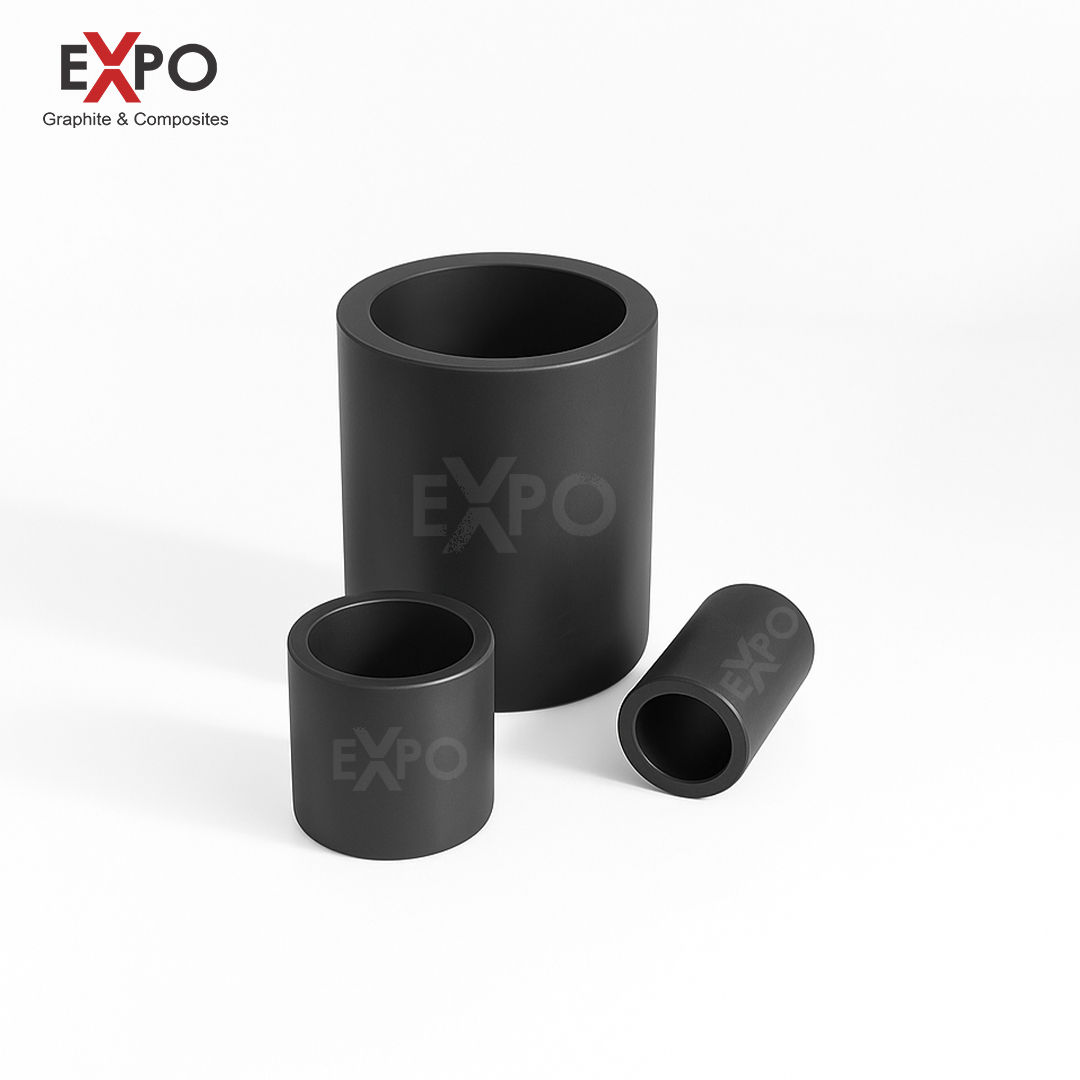

Graphite crucible

Graphite Lubricating Bushing is a strong part used in machines to reduce friction between moving parts. It’s made from graphite, which is naturally slippery, so it doesn’t need extra oil or grease. It works well in high heat and tough conditions. This bushing helps machines run smoothly and last longer with less care.

Description

Graphite Lubricating Bushing – Easy Explanation

A graphite lubricating bushing is a part made from graphite, a type of carbon material. The special thing about this bushing is that it can lubricate itself—which means it doesn’t need oil or grease to work smoothly. This makes it very useful in many machines and industries.

Where is it used?

- In Hot Places

Graphite bushings are great in high-temperature environments. For example, in factories where metals are melted or heated, machines can get very hot. These bushings work well even at high heat and do not get damaged. - In Chemical Plants

Some machines work with strong chemicals like acids or cleaning liquids. Many materials can break down in these harsh places—but graphite doesn’t. It can resist chemicals, so it lasts longer in these situations. - In Moving Machines

When parts of a machine rub together, they create friction. Too much friction can damage the machine. A graphite lubricating bushing helps reduce friction, making sure the parts move easily without getting damaged. - In Clean or Hard-to-Reach Places

Because it doesn’t need extra oil, a graphite bushing is useful in places where you can’t easily add grease, or where you want to keep things clean, like in food or medical equipment. - In Eco-Friendly Systems

Since you don’t need to use oil or grease, there’s less mess and less pollution. This makes graphite bushings a better choice for the environment.

Why Use Graphite Lubricating Bushings?

- They work without oil or grease.

- They last a long time even in hot or dirty places.

- They protect machines by reducing wear and damage.

- They are safe to use around chemicals.

- They help lower maintenance and repair costs.

5 Simple Advantages

- Self-Lubricating

It works smoothly without adding oil or grease, which saves time and money. - Handles High Temperatures

It can work well in very hot machines without breaking or melting. - Resistant to Chemicals

It does not get damaged by harsh liquids like acids or cleaning chemicals. - Less Maintenance Needed

It doesn’t wear out easily, so you don’t need to replace it often. - Environmentally Friendly

No extra oil means less pollution and cleaner machines.